Products & Services

Static Process Equipment

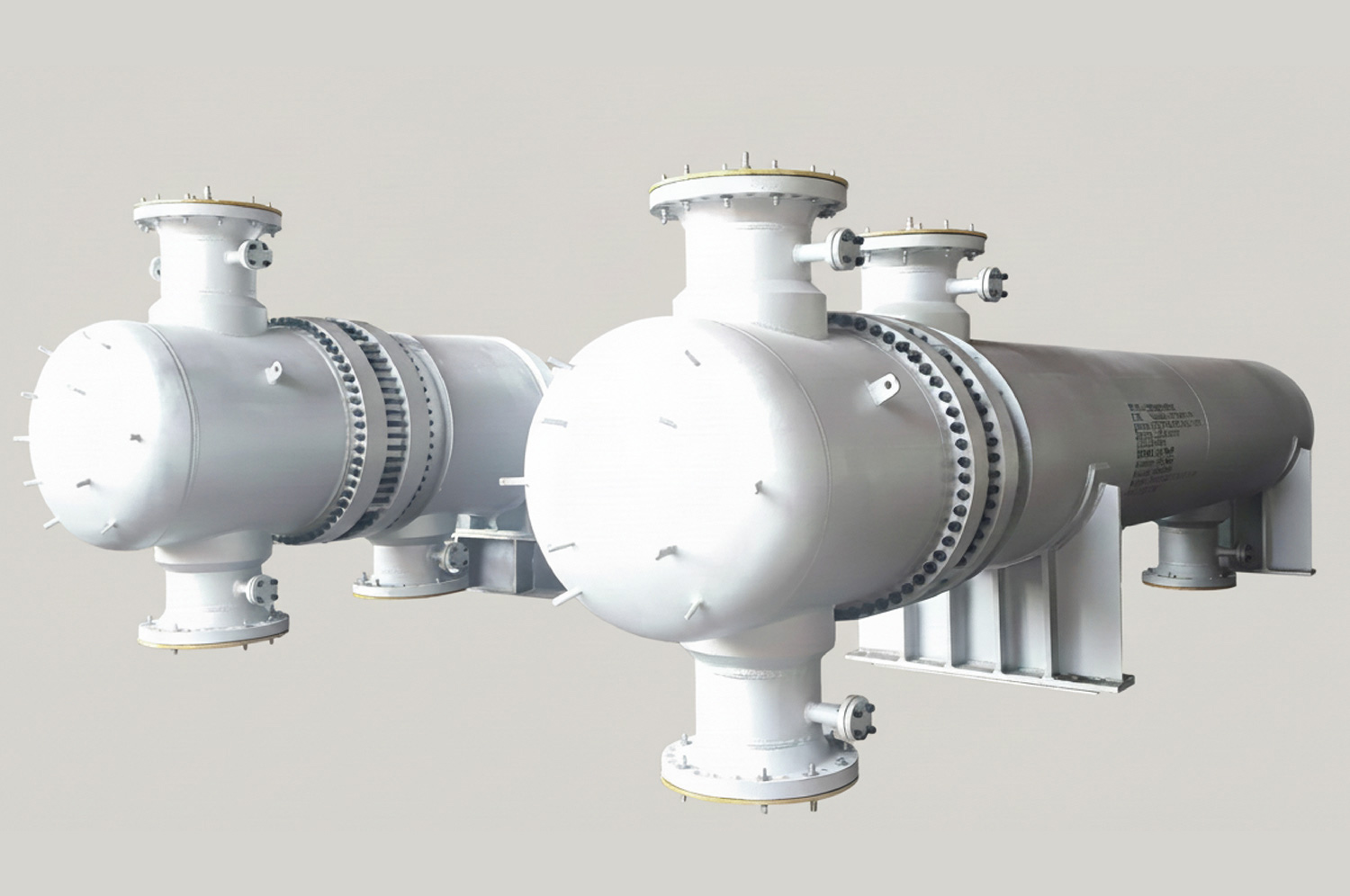

Heat Exchangers

With state-of-the-art machining facilities, a highly skilled workforce, and streamlined operations, heat exchangers have long been at the core of our manufacturing expertise. We specialize in the complete design and fabrication of heat exchangers using a wide range of materials, including Carbon Steel (CS), Alloy Steel, Stainless Steel, Duplex Stainless Steel (DSS), and other special materials as per customer requirements.

Our portfolio includes a comprehensive range of Shell & Tube Heat Exchangers, with a strong focus on high-pressure and exotic metallurgy applications. All products are manufactured and tested in compliance with TEMA and ASME standards, ensuring superior quality, safety, and performance.

Pressure Vessels

We are fully equipped to design, manufacture, and supply a wide range of pressure vessels for diverse applications across the oil & gas, petrochemical, power, fertilizer, and chemical industries. Our capabilities span Carbon Steel, Alloy Steel, Stainless Steel, Cladded, SDSS and other special materials as per client requirements.

Over the years, we have successfully delivered pressure vessels up to 47 meters in length, 6 meters in diameter, and 110 tons in weight—managing every stage from design to fabrication with precision and reliability. All vessels are manufactured and tested in strict compliance with ASME standards.

Reactors

Our collection of high-pressure, high-temperature and high-metallurgy reactors are a great fit for oil and gas refineries, as well as the petrochemical, fertilizer and chemical industries across the globe.

Columns & Tower

Our expertise is in manufacturing an extensive range of columns using materials like Alloy Steel, Stainless Steel and Carbon Steel, Cladded with packing and demister pads, etc., manufactured as per ASME, Section VIII. We are also equipped to design and manufacture various sizes of columns based on customers’ requirements and specifications, which include packed columns as well as tray towers.

Modular Skids

At Sudhir Brothers, we specialize in creating ingenious fabrication solutions tailored to meet unique industrial applications. Our metering and cooler skids are custom-designed and built to precise client specifications for the oil refinery, petrochemical, and natural gas industries.

Engineered for performance, reliability, and durability, our skids consistently meet the highest industry standards and have been successfully installed across numerous facilities for leading clients over the years.

Special Equipments

Silos/Hoppers | Cooker | Toaster | Maturator | Crystalizer | Storage Tanks | Equipments for Sulphuric Acid Plant | Hot Metal Ladle

API Monogrammed LSAW pipes as per API 2B

With years of industrial experience and advanced equipment technology, Sudhir Brothers is capable of meeting your LSAW Pipes needs and requirements ensuring high-quality and reliable products.

| PRODUCT | SIZE/RANGE | THICKNESS | SPECIFICATION |

|---|---|---|---|

|

Carbon Steel & Alloy Steel Longitudinal with Circumferential Seam submerged ARC Welded Pipes |

32 NPS (813 mm) to 200 NPS (5080 mm) | 1/2 to 5" | API 2B |

| Sudhir Brothers is capable of supplying pipes with a maximum length of 18 meters & an individual weight of upto 80 metric tons. | |||